Thanks to the high speed DSP core, the UC100 can make the interpolations and other timings much more precise than Mach3 could ever do using the traditional standard Parallel port driver. The UC100 implements linear and arc interpolation routines with trajectory planner, communication routines, limits and homing functions handling and it has nearly all the functions (with some limitations) as what Mach3 supports with the Parallel port driver. The UC100 looks like a simple USB to Parallel port converter module, but it is much more than this.

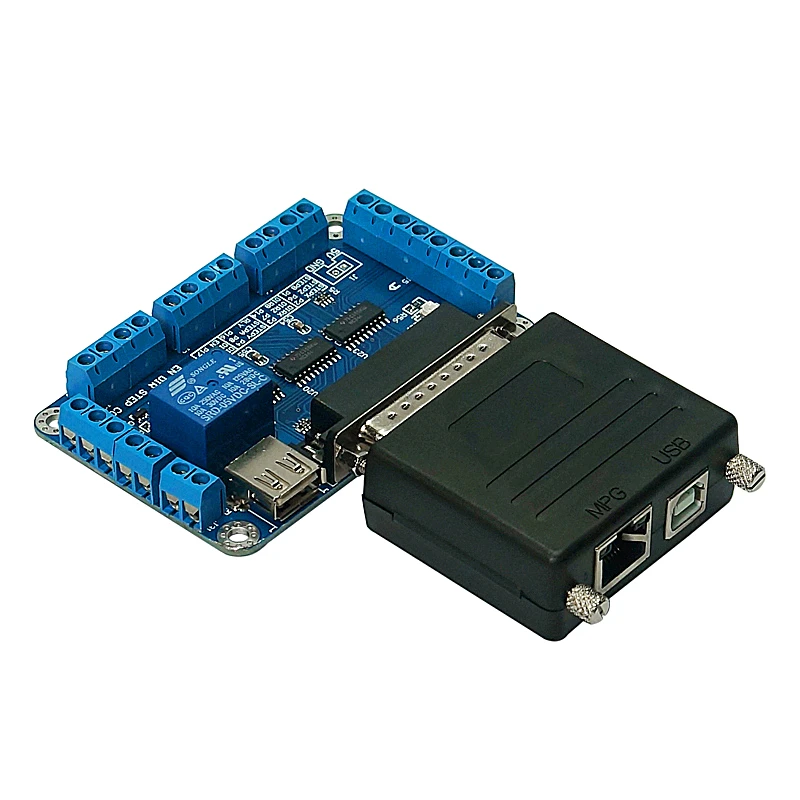

The UC100 controller connects to the PC via the common USB port.

The UC100 motion controller overcomes these problems by removing all time critical tasks from the control computer and Windows and executing all these tasks inside its own high speed DSP control chip. If the computer gets overloaded by Mach3 or by running other software(s) in the background may leads to a lagging of the G-code code execution to even a falter in the motion interpolation which may lead to a catastrophic failure of some applications.Īnother problem with is that Parallel Port is obsolete and none of the new computer have this kind of port built in anymore. As the output signals frequency gets higher with using todays more and more advanced motor control electronics, Mach3 takes more processor time of the computer. Windows is not a realtime operating system and therefor it is a difficult and CPU time consuming task for Mach3 to generate these signals in a precise manner. Traditional CNC software such as Mach3 uses the computer's parallel port (also known as printer port or LPT) and sending all signals via this port.

0 kommentar(er)

0 kommentar(er)